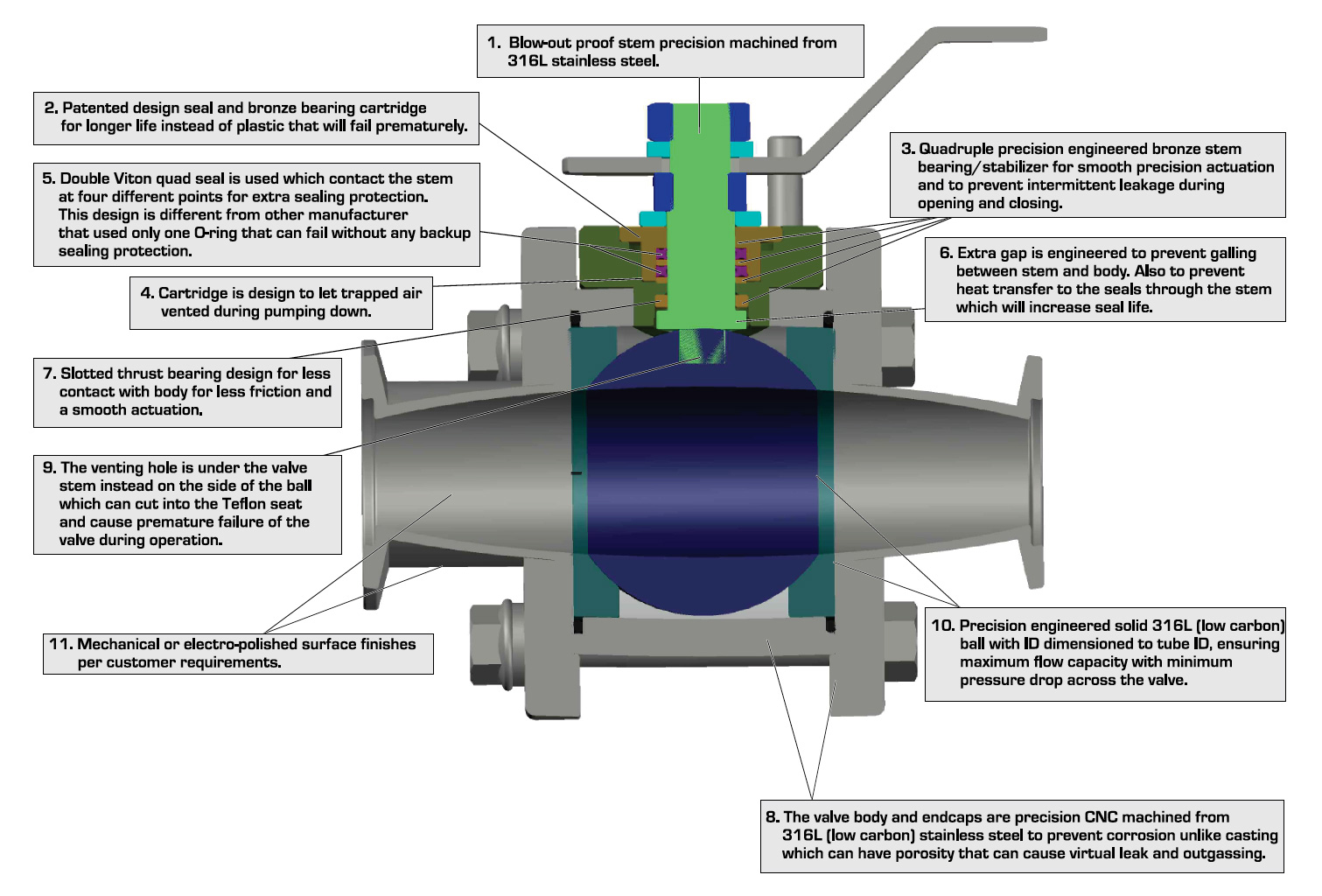

Highvac ball valves are offered in various sizes with different end connection including custom ends per customer specifications. All of Highvac ball valves parts including the stem, body and end caps are precision engineered and CNC machined from 31 BL [low carbon) stainless steel.

The ball has a vent hole drilled under the stem and not at the side that can cut into the Teflon seat under the constant sealing pressure and cause premature failure while opening and closing. The vent hole also serve the purpose of pumping the cavity between the ball and the body.

The valve is opened and closed at (¼ turn). Highvac ball valves stem are sealed with a patented and revolutionary design using two quad rings that makes contact at four different points on the stem to create a failsafe and leak free valve and also a longer period between maintenance. The valve stem is also stabilized with four special bronze thrust bearings and bushings. Highvac valves ball and end caps are fully ported for straight through flow and a higher conductance.

Valve Specifications

End Connection: NW 16 – ISO 100 (Custom ends also available)

Temperature Range: Bakeable to 302 F

Operating temperature: 375 F

Stem Seal: Double Quad-ring Viton seal standard*

Ball seats: Virgin teflon

Leak rate: Less than 1 X 10-9 std.cc/ sec.

Actuation Type: Manual

Valve parts: 316L (low carbon) Stainless Steel

Operating Pressure: 80-120 psig

Stem stability: Four bronze thrust washer/guide bearing

Fully ported ball: Electropolished surface finish for high purity application available

Ball Valves Applications

Highvac Ball Valves offer straight through high conductance flow. They are ideal for application such as LPCVD, MOCVD, PECVD etc. Ball valves can also be used in rough pumping.

Benefits

• Sizes NW 1 6 through ISO 1 DO

• CNC machined from 316 I stainless steel

• Fully ported through for high conductance

• Ball seat engineered for continuous seal

• Various configuration available

• Eliminate virtual leak

• Cycle life 35000 cycles