Highvac Ball Valve

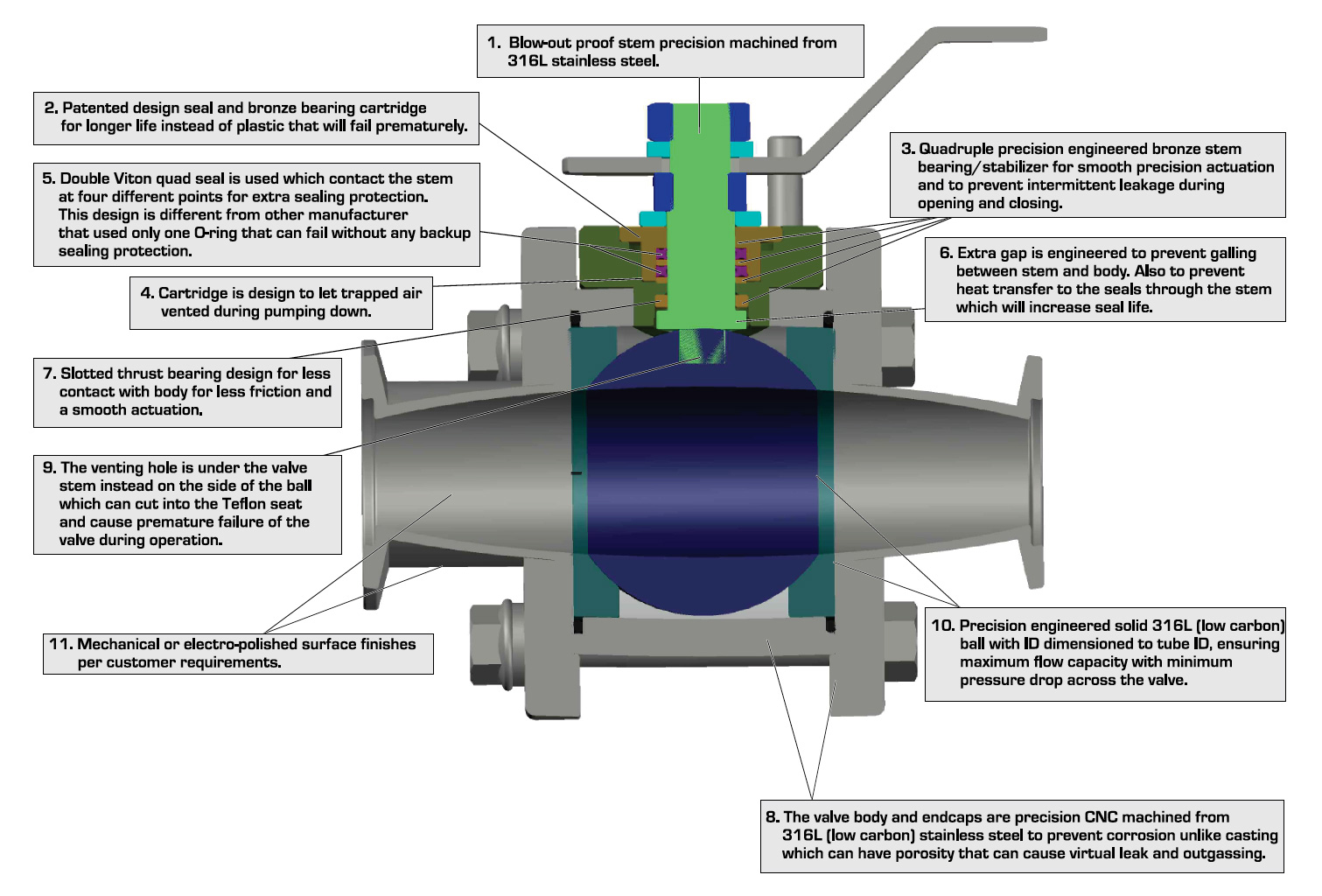

Highvac ELS series (extra life service) ball valves are designed for high conductance with uninterrupted flow. They are offered in various sizes from 2” to 6” with different end connection including custom ends per customer specifications. The valves are design with extended length end connection allowing for easy access for mounting and dismounting. All of Highvac ball valves feature a floating ball design for low torque and increased cycle life. Highvac ball valve parts including the stem, body, ball and end connections are precision engineered and CNC machined from 316L (low carbon) high corrosion resistance stainless steel. This design eliminate virtual leak that is caused by air bubbles trapped during the casting process within the valve body from casted valves that has been a problem within the industry for a very long time until now.

Highvac ELS series (extra life service) ball valves are designed for high conductance with uninterrupted flow. They are offered in various sizes from 2” to 6” with different end connection including custom ends per customer specifications. The valves are design with extended length end connection allowing for easy access for mounting and dismounting. All of Highvac ball valves feature a floating ball design for low torque and increased cycle life. Highvac ball valve parts including the stem, body, ball and end connections are precision engineered and CNC machined from 316L (low carbon) high corrosion resistance stainless steel. This design eliminate virtual leak that is caused by air bubbles trapped during the casting process within the valve body from casted valves that has been a problem within the industry for a very long time until now.

Three Piece Valve Design

Highvac ball valves feature double VitonR quad ring stem seal and a redundant body seal design. These highly precise CNC machined made valves are ideal for high cycle applications. The three piece body design offers many advantages, including installation flexibility, elimination of the need for two sets of flanges, and ease of in line and out of line servicing. These time-saving features are beneficial for process application to reduce downtime. During maintenance, the actuator and accessories can remain mounted on the valve body. The entire valve and actuator assembly is easily reinstalled.

To perform in line maintenance, remove the body bolts on opposing sides of the center body, loosen the 2 bolts at the top of the valve and swing the body up. The valve can swing to the left or right depending on which bolts are removed. All body components can be serviced in this position without disturbing the piping system. The two piece ball valve design required total removal from the line for maintenance.

Body

Highvac 3/4” – 6” valve bodies are CNC machine from 316L (low carbon) high corrosion resistance stainless steel to achieve the highest quality. This design will eliminate virtual leak compare to casted body. All bodies are marked with a part number, size and direction of flow for easy installation. The body is engineered to fit in the end flanges that is design with a counter-bore for easy alignment during re-assembling after maintenance.

Ball

The ball is CNC machined from 316L (low carbon) stainless steel designed with vent holes to allow for trapped air between the ball and cavity to be pumped preventing virtual leak. The ball is polished to a smooth mirror finish to acquire maximum sealing during opening and closing. Highvac valves ball are fully ported for straight through uninterrupted flow that allow for high conductance.

Seat

The valve seats are CNC machined from virgin TeflonR rather than injection molding process. This ensures bi-directional leak tight sealing and possible outgassing elimination with low operating torque. The seats are designed for minimum contact and constant sealing during cycling. This relieves pressure past the upstream seat, and positive preloading to ensure vacuum sealing.

TeflonR is our standard seat material. Optional seat materials provide versatile performance in a range of applications.

Stem Seal Package

The valve is opened and closed at (¼ turn) by the valve stem. Our valve stem is sealed with a patented and revolutionary design using two VitonR Quad Rings and four bronze bearings to reduce torque and prevent galling from tilting side to side. This design guaranteed smooth and leak free operation while prolonging the time between maintenance.

Actuation

Highvac valves are opened and closed at (¼ turn) by turning the valve stem via handle. Because of the higher initial torque to open and close ball valves 3/4” – 2” a lever type handle is fitted to the valve. The increase of torque in larger sizes 3”-6” makes it extremely difficult for opening and closing. Highvac is the first in the industry to introduce the manual gearbox with a hand wheel with high gear ratio to make opening and closing very easy. The gearbox is equipped with an open and close position indicator at the top to let the operator knows the position of the ball. This design reduces foot print dimension by as much as 25% at no extra cost. When compare to other manufacturers of ball valves larger than 2” it required a space at approximate 18” in both direction for the opening and closing. This is because of the long lever type handle design used, not mentioning the high amount of energy required.

Valve Specifications

End Connection: NW 16 – ISO 160 (3/4” – 6”) custom ends available

Temperature Range: -450 c (-500 F) to 246’C (475’F)

Standard Operating temperature: 302 F

Stem Seal: Double VitonR Quad-ring seal standard

Ball seats: TeflonR

Leak rate: Less than 1 X 10-9 std.cc/sec.

Actuation Types: Manual (handle), Pneumatic, gearbox or combination.

Air to open air to close, air to open spring to close

Standard Valve parts material: 316L (low carbon) Stainless Steel

Pneumatic Operating Pressure: 80-120 psi

Stem stability:Four bronze thrust washer/guide bearing

Fully ported ball: for maximum conductance

Electro-polish surface finish for high corrosion resistance available

Ball Valves Applications

Because of the robust design and high corrosion resistance. This make our valve favorable for application where particle contamination is imminent. Because of the unique design of ball valves. The seat continuously wipe and seal the ball during cycling this design make the valve demanding by OEM to be used in particle rich application such as scrubber isolation in process equipment in industry such as LPCVD, MOCVD, PECVD processing.

Features and Benefits

• End Flange: NW 16 through ISO 160 (Special Ends Are Available Upon Request)

• CNC machined from 316L stainless steel

• Fully ported through for high conductance

• Ball seat engineered for low friction and continuous seal

• Various custom configuration available upon request

• Eliminate virtual leak

• 3 piece design makes inline maintenance possible while maximizes heat reduction.

• 3 piece design account for 25% weight reduction compare to other valves of the same type.

• Valves are helium leak tested while cycling

• Cycle life: 35000 cycles

MANUAL BALL VALVES

Click for larger view

| Part Number | A | B | C | D | E | F | DRAWING | Tube Size | Actuation Type | End Flange | Bore Size | Unit Price |

| BV75M | 2.25 | 2.25 | 6.1 | 3.7 | 3.7 | 1 | 3/4″ | lever handle | NW16 | 0.75 | $265 | |

| BV10M | 2.5 | 2.5 | 6.1 | 3.9 | 4.2 | 1 | 1″ | lever handle | NW25 | 0.875 | $375 | |

| BV150M | 3.97 | 3.5 | 8.75 | 4.9 | 6.1 | 1 | 1 1/2″ | lever handle | NW40 | 1.375 | $775 | |

| BV200M | 4.5 | 4.1 | 8.75 | 5.5 | 7.1 | 1 | 2″ | lever handle | NW50 | 1.875 | $985 | |

| BV325M | 6.75 | 5.5 | 10.1 | 7.5 | 8.1 | 1 | 2.5″ | lever handle | ISO63 | 2.375 | $3,100 | |

| BV300M | 6.75 | 6.12 | 6.5 | 12.1 | 8.5 | 8.1 | 2 | 3″ | Gearbox/Wheel | ISO80 | 2.875 | Call |

| BV400M | 7.97 | 8.1 | 6.5 | 13.9 | 10.1 | 8.1 | 2 | 4″ | Gearbox/Wheel | ISO100 | 3.83 | Call |

| BV600M | 11.97 | 16.1 | 10.1 | 22 | 16.1 | 12.1 | 3 | 6″ | Gearbox/Wheel | ISO160 | 5.83 | Call |

Unless otherwise stated all dimensions are for reference only

|

PART NUMBER |

A |

B |

C |

D |

E |

DRAWING |

TUBE SIZE |

END FLANGE |

BORE SIZE |

Unit Price |

|

|

|

|

AIR TO OPEN AIR TO CLOSE |

|

|

|

|

|

|

|

|

BV75AA |

2.25 |

7.5 |

7.5 |

8.7 |

3.7 |

1 |

3/4″ |

NW16 |

0.625 |

$675 |

|

BV10AA |

2.5 |

7.75 |

7.5 |

9.1 |

4.2 |

1 |

1″ |

NW25 |

0.875 |

$795 |

|

BV150AA |

3.97 |

9.5 |

8.1 |

11.5 |

6.1 |

1 |

1 1/2″ |

NW40 |

1.375 |

$1,175 |

|

BV200AA |

4.5 |

9.75 |

8.1 |

12.1 |

7.1 |

1 |

2″ |

NW50 |

1.875 |

$1,685 |

|

BV325AA |

6.75 |

12.5 |

15.1 |

16.1 |

8.97 |

2 |

2.5″ |

ISO63 |

2.375 |

$3,900 |

|

BV300AA |

6.75 |

12.5 |

15.1 |

16.1 |

8.97 |

2 |

3″ |

ISO80 |

2.875 |

Call |

|

BV400AA |

7.97 |

13.25 |

15.1 |

17.25 |

10.1 |

2 |

4″ |

ISO100 |

3.83 |

Call |

|

BV600AA |

11.97 |

21.37 |

18.1 |

23.37 |

15.1 |

3 |

6″ |

ISO160 |

5.83 |

Call |

|

|

|

AIR TO OPEN SPRING TO CLOSE |

|

|

|

|

|

|

|

|

|

BV75AS |

2.25 |

7.5 |

7.5 |

8.7 |

3.7 |

1 |

3/4″ |

NW16 |

0.75 |

$975 |

|

BV10AS |

2.25 |

7.75 |

7.5 |

9.1 |

4.2 |

1 |

1″ |

NW25 |

0.875 |

$1,075 |

|

BV150AS |

3.97 |

9.5 |

8.1 |

11.5 |

6.1 |

1 |

1 1/2″ |

NW40 |

1.375 |

$1,400 |

|

BV200AS |

4.5 |

9.75 |

8.1 |

12.1 |

7.1 |

1 |

2″ |

NW50 |

1.875 |

$1,900 |

|

BV325AS |

6.75 |

12.5 |

15.1 |

16.1 |

8.97 |

2 |

2.5″ |

ISO63 |

2.375 |

$3,900 |

|

BV300AS |

6.75 |

12.5 |

15.1 |

16.1 |

8.97 |

2 |

3″ |

ISO80 |

2.875 |

$4,700 |

|

BV400AS |

7.97 |

13.25 |

15.1 |

17.25 |

10.1 |

2 |

4″ |

ISO100 |

3.83 |

$6,600 |

|

BV600AS |

11.97 |

21.37 |

18.1 |

23.37 |

16.1 |

3 |

6″ |

ISO160 |

5.83 |

$10,800 |